Global Precision Die Casting Solutions Provider – End-to-End Manufacturing

![]() Solutions & Capabilities – JUFENG Precision operates 2 specialized facilities with 120+ skilled professionals, equipped with advanced equipment, specializing in high-performance die casting molds and precision components.

Solutions & Capabilities – JUFENG Precision operates 2 specialized facilities with 120+ skilled professionals, equipped with advanced equipment, specializing in high-performance die casting molds and precision components.

![]() Established in 2010, 15+ years of industry experience.

Established in 2010, 15+ years of industry experience.

![]() Your precision partner – We optimize high-mix, low-to-medium volume projects with flexibility.

Your precision partner – We optimize high-mix, low-to-medium volume projects with flexibility.

![]() Certified quality – Our IATF 16949 and ISO 9001 certifications ensure consistent, high-performance die castings for demanding international markets.

Certified quality – Our IATF 16949 and ISO 9001 certifications ensure consistent, high-performance die castings for demanding international markets.

Our Services

Craftsmanship spirit, carefully crafting every spare part

CNC Machining Service

Complete range of machining with the automation of all procedures: Drilling, Milling, Turning, Tapping, etc.

Rapid Prototyping Service

Experienced engineering professionals carefully review aluminum die-casting and machined parts

Sheet Metal Fabrication

Excellent engineering team with over 10 years of experience in sheet metal processing and manufacturing

Die Casting Tooling Service

Engineers assist you with conceptual visualization, mold flow analysis, and complete mold design

End-to-End Die Casting Solutions

Die Casting Mold Design & Manufacturing - Precision Die Casting Tooling Solutions

Advanced Mold Simulation & Validation

Expert Mold Design Engineering Team

High-Precision Tooling Manufacturing

Mold Lifecycle Guarantee

Integrated In-House Mold Fabrication

Rapid Tooling Service (2-4 Weeks)

Advanced R&D Expertise

End-to-End Die Casting Solutions

Extensive Aluminum Alloy Expertise

Precision Quality Assurance

Specialized in Precision Low-to-Medium Volume Production

Full-Spectrum Precision Machining

Advanced Machining Capabilities

Engineering Excellence

Reliable Production & Delivery

Precision Quality Control

Proven Machining Expertise

Comprehensive Surface Treatment Solutions

Precision Quality Assurance

Engineered Packaging Solutions

Full Regulatory Compliance

Advanced Engineering Solutions

Precision Surface Excellence

JUFENG Precison Product Showcase

We continuously provide high-quality die castings for numerous customers worldwide.

State-of-the-Art Facilities

JUFENG Precision is equipped with state-of-the-art facilities, ensuring high-mix, high-quality, and high-precision products.

High-tolerance Mold Manufacturing Machines

High Precision Aluminum Die Casting Machines

Multi-Axis CNC Machines

Post-Processing Lines

High Precision Aluminum Die Casting Machines

Multi-Axis CNC Machines

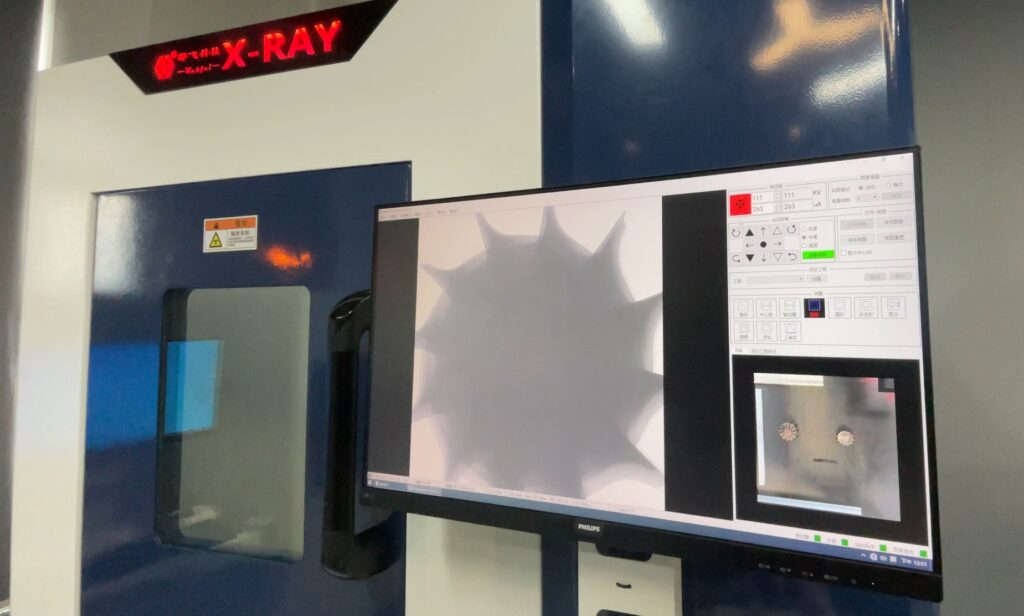

JUFENG Precision Laboratory

Die-Casting Quality Assurance

Our state-of-the-art laboratory is equipped with precision inspection and testing equipment, ensuring rigorous quality control throughout the die-casting and machining processes. From material analysis to dimensional verification and surface integrity testing, we guarantee component reliability at every production stage—meeting the highest industry standards.

First Article Inspection (FAI) on every die-cast part with meticulous attention to detail

High-precision CMM scanning for micron-level dimensional accuracy

In-process quality checks by trained QC specialists

Optical projection measurement for rapid and reliable dimensional verification

Incoming material certification to meet high standards

X-ray porosity testing to validate internal integrity of castings

JUFENG Precision – Your Trusted Partner for Molding, Die Casting & Precision Machining Solutions

We provide full services of die casting and add value to global clients with our strengths

Flexible Manufacturing Solutions for Die Casting Projects

Prototype development to full production runs, specialize in high-mix, low-to-medium volume manufacturing, cost-optimized solutions perfect for: Startups requiring design validation SMEs needing production flexibility Established buyers with specialized applications

Expert Engineering Team and State-of-the-Art Facilities

Skilled professionals providing innovative and efficient manufacturing solutions. Advanced die casting, CNC machining, and precision measurement equipment.

Rapid Response & Reliable Delivery

Rapid prototyping and efficient production ensure on-time project completion.

Lean & Efficient Production

Streamlined processes from material sourcing to final delivery for maximum cost-effectiveness.

15+ Years of Specialized Experience

Expertise in aluminum, zinc, and magnesium die casting for diverse industries.

Rigorous Quality Assurance

Strict control over materials, processes, and technologies to meet global standards.

Collaborative Customer Approach

Early engagement in product development, offering turnkey solutions tailored to your needs.

Sharing the Voices of Clients

Worldwide clients have regarded JUFENG Precision as a trustworthy and reliable partner in development and production of die casting projects.

Michael

Technical Buyer (USA)

We truly appreciate our partnership with JUFENG Precision. The quality and performance of your products have shown remarkable improvement, and we are confident that the coming year will be a successful one for both our companies. A special thanks to your team for driving cost reductions and ensuring on-time deliveries-your support has been great.

David

Project Engineer (UK)

JUFENG Precision consistently delivers excellence, whether for new projects or ongoing production parts. Their extensive expertise and strong support are highly beneficial. I particularly appreciate their outstanding DFM capabilities, rapid response, and reliable on-time delivery.

Marco

Mechanical Engineer & Technical Buyer (EU)

JUFENG Precision provides high-quality die casting components that meet our specifications. We anticipate further strengthening our partnership in the coming year through expanded cooperation.

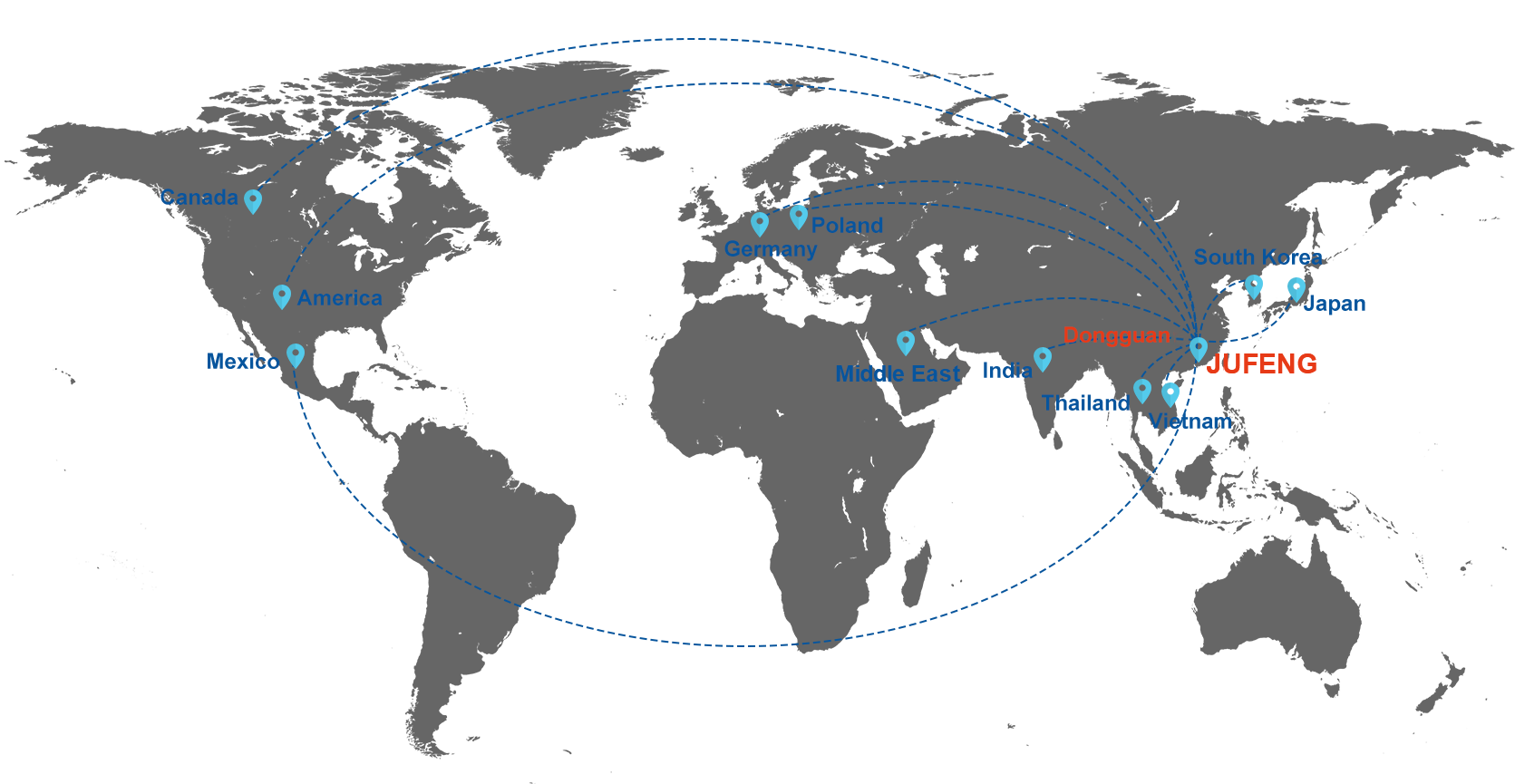

JUFENG Precision & Customer Location

JUFENG Precision is supplying die casting parts to massive customers worldwide, mainly distributed in Europe, North America, Southeast Asia, Northeast Asia, the Middle East, and other regions. No matter where our customers are, we are always here to satisfy and serve them.

Have A Query?

We have mapped out some questions and answers for you to browse quickly.

We specialize in aluminum, zinc, and magnesium alloys (ADC12, A380, A360, DC01, ALSI12, ZAMAK, AZ91D, etc.), including eco-friendly options.

Yes. Integrated services: mold design & making → die casting → CNC machining → surface treatment → assembly.

ISO 9001 & IATF 16949 certified with 100% dimensional inspection (CMM/X-ray) and material certification.

15-25 days for mold making and samples (depending on complexity).

Automotive, medical, telecommunication, lighting, robotic, aerospace, consumer electronics, and industrial equipment.

We’re an IATF 16949-certified die casting manufacturer with 15+ years of in-house production experience in China.

Fully equipped CNC department (±0.01mm tolerance) and surface treatment services (powder coating, anodizing Class II, etc.).

Recycled aluminum alloys, waste heat recovery systems, and IATF 16949-compliant processes.

Up to 650mm x 500mm with 10kg max weight for aluminum. Custom solutions available.

Standard: ±0.1mm. High-precision: ±0.01mm with our CNC machining.

Anodizing, powder coating, E-coating, painting, plating, passivation, sandblasting, shot blasting, laser etching, etc.

Yes. No MOQ for prototyping; optimized production for 500-50,000pcs batches.

Strict NDA compliance with secure data management (ISO 27001 standards).

Yes. Our 800T-1,250T machines achieve 0.8mm wall thickness with vacuum-assisted and mold temperature control technology.

In-process CMM checks + 3D scanning with 0.01mm repeatability.

30% standby capacity + express tooling channels for 25% faster delivery vs industry average.